Arc Flash Hot Sticks and Voltage Testers

Hot Sticks and Voltage Testers, such as Tic Tracers are an extremely useful troubleshooting tool and are needed in a variety of industries. They can be used to check fuses, breakers panels, locate heating wires within walls, locate breaks in insulated wire and heating elements, or to check voltage in outlets, switches and transmission lines. These testers can also be used to do a safety check on power tools and appliances.

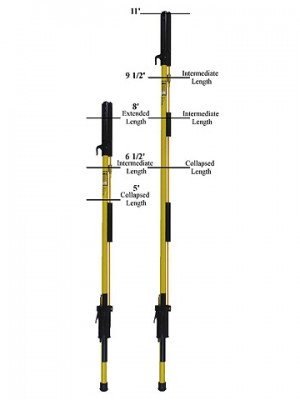

Our Telescoping Hot Stick comes equipped with a universal spline end and hot stick probe. In addition, the MS-USTS- comes with the tip lock operational feature standard. The operator can simply lock the end section into second to last section if necessary to obtain maximum flexural/tensile strength from the extended stick to open/close stubborn equipment.

The stick has been engineered so additional fiberglass has been added where the highest strength is required and removed where it is not required. The result is a telescopic stick able to withstand the rigors of line operations and still offer the utmost in lightweight for portablility. The outside surface texture provides a positive gripping surface even in wet conditions. All operating buttons are CNC machined from very high strength and water resistant engineered solid polymer rod to provide maximum mechanical strength.

All telescopic fiberglass sticks also come equipped with the new EZ tip lock button replacement feature. No more complete stick disassembly to replace the tip lock button which usually winds up as a complete section 1 fiberglass changeout. The EZ tip lock button replacement feature permits the tip lock button to be replaced easily and rapidly WITHOUT disassembly of the entire stick, a costly and time consuming operation.

All telescopic hot sticks are manufactured from the highest grade electrical rated fiberglass and meet or exceed all applicable industry performance criteria including ASTM F711, ASTM F1826, and OSHA 1926.951(d).

| Model | Size | Closed Length | Base Diameter | No. of Sections | Weight | Operating Length | Price |

| Ground Operable | |||||||

| MS-USTS050 | 50 ft. | 68” | 3 1/2” | 11 | 20 lbs* | 50′,45′,40′,35′,30′,26′,21′,17′ | Call for price |

| MS-USTS045 | 45 ft. | 66” | 3 1/8” | 10 | 16.5 lbs* | 45′,40′,35′,30′,26′,21′,17′ | Call for price |

| MS-USTS040 | 40 ft. | 65” | 2 7/8” | 9 | 13.5 lbs* | 40′,35′,30′,26′,21′,17′ | Call for price |

| MS-USTS035 | 35 ft. | 63” | 2 5/8” | 8 | 1.1 lbs* | 35′,30′,26′,21′,17′ | Call for price |

| MS-USTS030 | 30 ft. | 62” | 2 3/8′ | 7 | 8.9 lbs* | 30′,26′,21′,17′ | Call for price |

| MS-USTS025 | 25 ft. | 60” | 2 1/8′ | 6 | 6.9 lbs | 26′,21′,17′ | Call for price |

| MS-USTS020 | 20 ft. | 58” | 1 7/8” | 5 | 5.2 lbs | 21′,17′ | Call for price |

| MS-USTS016 | 16 ft. | 56” | 1 5/8′ | 4 | 4 lbs | 16′,12′ | Call for price |

| Bucket Operable | |||||||

| MS-USTS012 | 12 ft. | 30” | 2 5/8” | 7 | 5.7 LBS* | 12′ | Call for price |

| MS-USTS010 | 10 ft. | 28” | 2 3/8′ | 6 | 4.7 LBS* | 10′ | Call for price |

| MS-USTS008 | 8 ft. | 26” | 2 1/8′ | 5 | 3.7 LBS | 8′ | Call for price |

| MS-USTS006 | 6 ft. | 26” | 1 7/8” | 4 | 2.5 LBS | 6′ | Call for price |

| MS-USTS004 | 4 ft. | 26” | 1 5/8′ | 3 | 2 LBS | 4′ | Call for price |

Custom design your own straight stick in the following manner. First, determine the required stick length in feet, up to 10 foot maximum. This is the -XX- part of the part number. For example, -06- is 6 foot, -10- is 10 foot, etc.

Lastly, choose the two end components for the stick, -YY- being the first end and -ZZ- the second end. Your selections: -HP- is hot stick probe, -SE- is universal spline end, -EC- is rubber end cap, -SH- is switchhead, -DH- is disconnect head, -DP- double prong, -RP- is rotary prong and -RB- is rotary blade.

If you desire a plastisol non-breakable metal hanger which is user adjustable add -HGR- to the end of the catalog number.

Straight sticks meet or exceed all applicable industry performance criteria including ASTM F711, ASTM F1826 and OSHA Sub. V sec. 1969.951(d).

Design Your Own Hot Stick

| Model | Length | End One | End Two | Price |

| MS-USSS004-X/Y | 4 | Call for price | ||

| MS-USSS006-X/Y | 6 | Call for price | ||

| MS-USSS008-X/Y | 8 | Call for price | ||

| MS-USSS010-X/Y | 10 | Call for price | ||

| Hot Stick Accessories | ||||

| MS-USSAOEC | Rubber End Cap | Call for price | ||

| MS-USSAOSE | Universal Spline | Call for price | ||

| MS-USSAOSH | Nema Switchead | Call for price | ||

| MS-USSAHGR | Plastisol Hanger | Call for price | ||

| MS-USSAODH | Disconnect Head | Call for price | ||

| MS-USSAOHP | Hotstick Probe | Call for price | ||

| MS-USSAODP | Double Prong | Call for price | ||

| MS-USSAORP | Rotary Prong | Call for price | ||

| MS-USSAORB | Rotary Blade | Call for price | ||

| MS-USSAASD | Ice Wacker | Call for price | ||

| MS-USSAPSC | Shoestring Cutter (Plastic) | Call for price | ||

| MS-USSAMSC | Shoestring Cutter (Metal) | Call for price | ||

| Hot Stick Storage Bag | Call for price | |||

Shotgun Hot Sticks External & Internal Operating Rod

The MS-USSGXEREC/SE shotgun sticks utilize two external rod guides to assure a smooth opening and closing operation when in use. The MS-USSGXEREC comes equipped with a rubber end cap while the MS-USSGXERSE comes with a universal spline. Protective bags are available.

External Rod Shotgun sticks are available in 4 1/2′, 6 1/2′, 8 1/2′, 10 1/2′ and 12 1/2′ lengths. The special stripe feature (pat pending) indicates to the lineman where the hook will open. Stripe Up means Hook Down!

Internal Rod Shotgun sticks are available in 4 1/2′, 6 1/2′, 8 1/2′, 10 1/2′ and 12 1/2′ lengths. The stripe feature (pat pending) indicates to the lineman where the hook will open. Stripe Up means Hook Down! All Hot Sticks meet or exceed all ASTM and OSHA requirements.

| Model | Length | Weight | Price | |

| Rubber End Cap | ||||

| MS-USSG004EREC | 4.5′ | 5 LBS* | Call for price | |

| MS-USSG004IREC | ||||

| MS-USSG006EREC | 6.5′ | 5.4 LBS* | Call for price | |

| MS-USSG006IREC | ||||

| MS-USSG008EREC | 8.5′ | 5.9 LBS* | Call for price | |

| MS-USSG008IREC | ||||

| MS-USSG010EREC | 10.5′ | 6.8 LBS* | Call for price | |

| MS-USSG010IREC | ||||

| Universal Spline | ||||

| MS-USSG004IRSE | 4.5′ | 5 LBS* | Call for price | |

| MS-USSG004ERSE | ||||

| MS-USSG006IRSE | 6.5′ | 5.4 LBS* | Call for price | |

| MS-USSG006ERSE | ||||

| MS-USSG008IRSE | 8.5′ | 5.9 LBS* | Call for price | |

| MS-USSG008ERSE | ||||

| MS-USSG010IRSE | 10.5′ | 6.8 LBS* | Call for price | |

| MS-USSG010ERSE | ||||

Voltage Proximity Testers are a relatively simple testing instrument that enables electricians and other uses to locate, trace and identify common electrical problems. These testers can locate wires behind walls, underground, and inside junction boxes. Others are designed to find blown fuses or test light fixtures. Some testers can even locate neutrals, ground faults, and high voltage lines without interrupting power. Most products are capable of continuity checks and audible continuity measurements. Continuity checks test a circuit for completeness, while audible continuity measurements beep when probes touch each other.

Tic Tracer – Proximity AC Voltage Detector

The Tic Tracer is adaptable to hot sticks and is used to check fuses, breaker panels, power outlets, load break connectors, and transmission lines. The Tic Tracer has a high voltage range (1500-122,000 volts) and a low voltage range (25-1500 volts). This handy tool will allow the user to detect electricity without having to break into power lines. The signal of the beeper will become louder as a person comes closer to live electrical lines. The risk of touching live electrical wires is non-existent with this handy tool. The Proximity Voltage Detector can also be used to check power tools and to see if they are properly grounded. Users can also test whether AC power is connected to outlets, lamps, and/or switches. This tool is lightweight yet rugged, has an integrated switchguard and is made in the USA.

Non-Contact Voltage Detector up to 500kV

The Non-Contact Voltage Detector is used to verify live or de-energized conductors, and will warn of voltage from 230V to 500kV. As the tester is moved closer to the conductor or apparatus, a warning of voltage is indicated. This tester may be used with rubber insulating gloves or hot sticks with a splined universal end fitting. It is recommended that the tester is moved closer to the conductor until the warning is indicated or the unit touches a conductor, apparatus, or test point. Keep in mind, when using non-contact voltage detectors, it is extremely important to always verify proper operation. Immediately after checking a line or piece of equipment, the detector should be verified to reassure the proper functioning of the tool. This extremely useful tool comes complete with a case and shotgun adapter.

Precautions and Warnings

Anyone who uses hot sticks and voltage testers entrusts his/her personal safety to this instrument. For this reason, testing the tool’s operation on a flourescent lamp or known conductor of AC voltage is extremely important. If the unit is dropped, or for any reason a malfunction is suspected, test it before making checks or high voltage tests. Three phase feeder cables with conductors close together may self-cancel the field detected by the instrument; therefore, it is imperative to always separate such conductors by at least 4 inches before testing AC voltage.

When approaching an unknown voltage, especially a high one, always start with the unit switched to the ‘Low’ range. Then, approach the voltage from a distance. It is also important to use a “Hot Stick” at all times. Note that with the switch in the high range, the unit will only detect voltage above 1500 VAC.

Applications

- Checking fuses and/or breakers: Users may check screw-in type, cartridge type or resettable breaker type fuses with Tic Tracers. With the circuit energized, a good screw-in type fuse will create a whistle when the probe is placed on it. Good cartridge fuses and breakers should sound a siren on both ends, and across their length. Because the Tic Tracers detect the electrostatic field, it may be necessary to remove the metal fuse panel cover, as it may act as a shield.

- Locating heating wire within walls: Will trace heating wires within plastered walls. A quickened signal indicates an energized wire; if it ceases, a break is located.

- Locating breaks in insulated wire and heating elements: Energize the wire or element and trace along it until the quickened ‘beep’ or siren ceases. This indicates the point of the break, or ‘open.’

- Outlets and Switches: Place probe tip against an outlet or switch contact; increased ‘beeping’ indicates voltage.

- Safety Check on Power Tools and Appliances: While the device is connected to AC voltage, touch the probe tip to the metal casing. Test with device switched off and on. No increase in beep rate indicates a safetly grounded tool or appliance.

- High Voltage Applications: With the unit switched in the High range, the insrument will detect voltages above 1500. Always use a Hot Stick in these applications.

- Loadbreak Connectors: Check for power at high voltage transformers at elbow test point.

- Transmission Lines: Determine which conductor carries power and if ground cables carry high static charge.

- TV High Voltage: Check picture tube and HV transformer.